Using yesterday’s experience, today’s tools, and tomorrow’s thinking, the Uniwell engineering team can help launch your product into new frontiers and expanding markets.

Count on our knowledge and professionalism to gain the edge in today’s competitive market.

We are easy to work with, eager to serve, and ready to help with all of your demands.

testtesttesttesttesttesttest

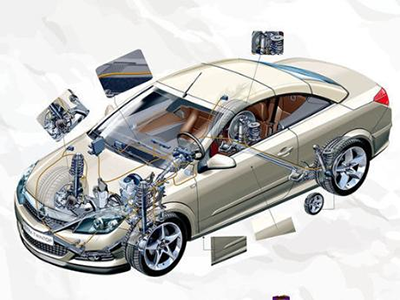

● High voltage systems bring heat and safety problems

● Delays and long lead times are common

● Strict rules add the risk of costly recalls

● Integrating harnesses with advanced vehicle systems is tough

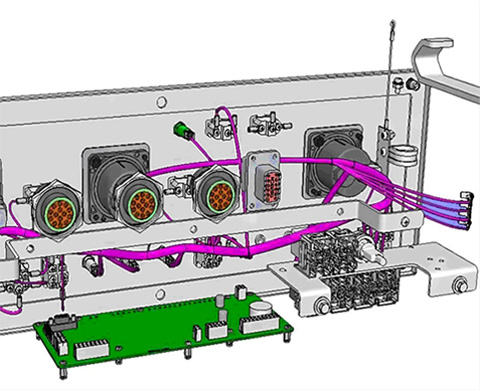

● Sealed and waterproof designs: high Ingress Protection (IP) rating, such as IP67 or IP68.

● Durable jacketing

● EMI/RFI shielding

● Vibration and abrasion tolerance

● Modular design

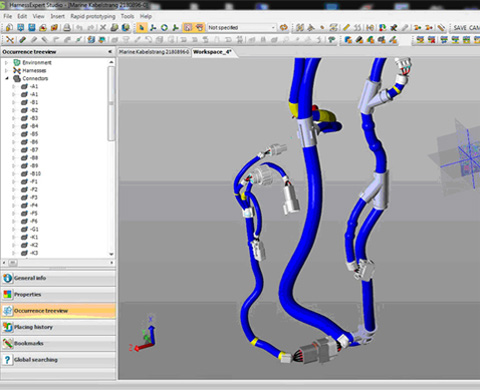

● Durability: Assemblies are built with robust materials to resist abrasion, oil, chemicals, and mechanical stress common in construction environments.

● Environmental Protection: Outer sheaths and protective tubing guard against moisture, dust, and UV exposure.

● Vibration Resistance: Harnesses are engineered to secure wires and prevent damage from constant vibrations.

● Customization: Assemblies are tailored to specific machine requirements, including length, complexity, and connector types, to ensure precise fit and function.

● Simplified Installation: By bundling wires into a single, manageable unit, harnesses reduce assembly time and complexity for OEMs

● Organized wiring: Saves space, simplifies installation, and organizes the complex electrical wiring in a forklift.

● Protection: The harnesses protect the wires from the harsh conditions including vibrations, moisture, chemicals, and abrasion.

● Optimized performance

● Essential for various functions: Integral to the operation of a range of systems, including lighting, ignition, engine control, battery management (for electric models), and onboard computers.

● Protection from harsh conditions: Assemblies are built to withstand UV exposure, extreme temperatures, vibration, and moisture, particularly for outdoor installations.

● High-voltage and high-current capacity: They are specifically engineered to handle the high-power demands of ESS, with both low- and high-voltage options available.

● afety and reliability: To prevent shorts and ensure long-term reliability, the cables are protected by a durable outer sheath and secured with various fasteners.

● Customizability

● UL certification

● High-voltage (HV) cables: Used for the main electric powertrain to connect the battery pack, motor controller, and motor. These cables feature thick-gauge wire and robust insulation.

● Low-voltage (LV) wiring: Manages all the accessory functions, such as lights, gauges, horn, turn signals, and the onboard charger.

● Connectors and terminals: These electromechanical devices join different electrical conductors. Connectors must be chosen for their ability to withstand vibrations, moisture, and temperature fluctuations common in LSV operating environments.

● Protective sheathing: Materials like PVC, Teflon, or specialized conduits protect the wire assembly from abrasion, heat, moisture, and other environmental hazards.

● Cable management: Items like clips, clamps, and heat shrink tubing keep the assembly neat and secure, preventing strain on the wires.

● Safety features: For street-legal LSVs, the harness must support critical safety components, including brake lights, seat belts, and mirrors, in compliance with federal and state regulations.